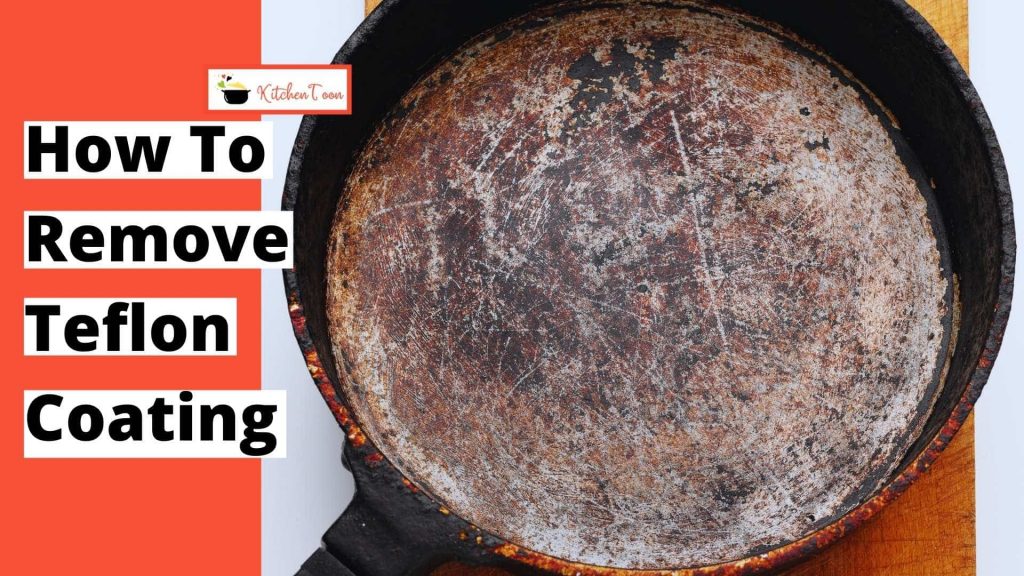

Due to its short lifespan, Teflon requires removal once it begins to wear out and release perfluorooctanoic acid, a toxic compound, for instance. Thus, we can easily remove the coating from cook materials and containers by using rough materials commonly referred to as abrasives such as sandblasting, walnut shell, baking soda, aluminum oxide, and metal scrubbers. Teflon coating refers to a fluorocarbon solid applied mainly to cookware or automotive parts. In cookware, it gives cooking materials a protective non-stick layer that prevents foodstuffs from sticking on the material’s surface. Besides, it makes the surfaces of the cook materials glossier and shinier.

Additionally, Teflon is among the plastic coating that has allowed friction and possesses non-conductive elements. These elements prevent the food prepared on a Teflon-coated pan or the raped eating staff from sticking. The layer has a short life in cooking materials such as pan that it starts scratching and peeling off in a certain period, say eight months since its application. Should we throw away the cooking pan once Teflon lifespan perishes? No, instead of discarding the cooking pan, more solutions are created, such as removing the Teflon coating, thus expanding the usage life of the cooking pan. Therefore, in this article, you’ll learn how to remove Teflon coating.

Disclaimer: I am definitely not going to suggest using the pan which’s coating is peeling off. Even though you remove the Teflon coating the cookware is still not in a good condition. The worst thing about it is food will stick to the pan when you use it.

Table of Contents

ToggleSoaking

Soaking the coated substance is the first method used to remove the Teflon coating.

- Place the pan in a sink, say, with half an inch of dishwasher soap and submerge it using boiling water.

- The pan should then get soaked in the solution for about twenty hours; thus, enhancing softness to the top layer of the Teflon.

- After soaking the pan, sprinkle baking soda onto its non-sticky interior surface and scrub it thoroughly using a scouring pad to strip off the softened Teflon.

- Repeat the above steps until no traces of Teflon gets left on the material surfaces.

In most cases, this method is used on scratched or maybe burnt the process does not need professional assistance. Hence, most homes can afford it in terms of financial status. Compared to other methods like aluminum oxide, this technique uses one stage to complete the whole process. Thus, soaking is amongst the most common non-industrial practice of removing Teflon coating.

Metal Scrubbers

The other method used is using rough materials such as metal scrubbers. In this case, Teflon coating is scrubbed using a metal scouring pad and baking soda. This method has automatic outcomes. No time required the process to complete, unlike the use of soapy water. Materials used in this method are easily accessible, thus making it affordable to all people. This technique is most used at home and rarely in the industries.

Watch this video as a reference:

Sandblasting

Use sandblasting is another technique used in the removal of Teflon coating. It involves using abrasives to remove applications in different circumstances, such as:

- Civil steel structure,

- The coated part in the aircraft, and

- Teflon stripping on a ship.

The method follows two steps;

The first step is the carbonization of the Teflon element called carbon-fluorine, and the last step is removing the carbonized part by sandblasting.

Thus, the process entails using powered machines to eradicate debris or coating on the surfaces of materials using high-speed compressed air. The carbonization process is tiresome and more expensive to minimize the risks for operators by creating a suitable environment for them. It is the most challenging method as one stage of carbonization cannot be enough to complete the process. Thus, several repetitive procedures are required to ensure that scratched Teflon is wholly stripped from the material.

Aluminium oxide method

Aluminum oxide is one of the professional techniques used to remove Teflon coating. Thus, professional advice is essential when using this procedure. This method of Teflon removal is generally used in industries, for example:

- Chemical industries

- Food industries

- Metal creating industries

In this case, aluminum oxide is used in removing the scratched coating from the containers used to pack food substances in the food industries. Due to the complexity of the technique, it effectively applies in industrial processes. Hence, this technique is complex for home use, given its approach and risk.

Use of massive temperature

Using the highest temperature of above five hundred degrees is another method used to eradicate Teflon coating. Although Teflon possesses the qualities that indicate its resistance to heat, adding temperature at a high level may help in this case. Elements like high service hardness, poor chemical reactivity, and the ability to resist change against the temperature bring challenges to this method. This method requires both environmental and organizational costs, thus making it not preferable by most people.

Use of walnut shell

The other method applicable in Teflon removal is the use of a walnut shell. Walnut shell blasting is mainly suitable for removing composite material from cookware made of aluminum. Hence, the technique effortlessly removes Teflon coating from the surfaces, which helps to extend the cooking material usability. Additionally, walnut shell cleans production machinery parts in the industrial process, removing the worn-out parts on their surfaces, helping to rejuvenate their non-sticking properties. However, whether done at home or in industries, walnut shell blasting does not damage the aluminum properties of the materials.

Frequently asked questions.

Does Teflon have a lifespan, especially in cookware?

Yes, it has. When you take good care, the lifespan will be longer.

How does one clear scratched Teflon surfaces?

Place the pan in a sink, soak in boiling water in the boiled water, then use baking soda and scrub.

Conclusion

In summary of the article, it is a clear indication that Teflon has a short service life. The burning may occur or scratch making it unpleasant on a cooking staff. Among the many types of coating, Teflon is the most preferred in homes and industries. It carries elements that enable it to resist water, and a low heat environment is considered the best in cooking pans.

Additionally, Teflon is advantageous in minimizing the flammability of cookware is it offers exceptionally high resistance to high temperatures. Teflon gives the materials dielectric strength which helps them in resisting high electrical power. To a few, despite the massive number of benefits ranging from non-stickiness to high chemical resistance, Teflon has its shortcomings due to the short lifespan of the material coating.

Removing the scratched layer helps the remained metallic substance continue with its service life. The use of the discussed method of Teflon coating removal is helpful in most areas. Some of these methods bring the quickest results, such as using a scouring pad and cooking soda. Other methods like the use of soapy water have to take time for the process to complete. Lastly, the industrial techniques must take some stages to get the best outs comes.

Hi, I’m Kimberley. I am a happy and adventurous person who enjoys writing about the finer details of the kitchen niche. My blog is where I can share all my thoughts and opinions with other passionate food lovers like me!

if you’re reading this then it’s probably safe to assume that you’ve stumbled across one of my blogs about the kitchen niche! I love writing informative blogs and review posts for those who are looking for a little bit more information before buying their next product.

Follow me on Twitter

2 thoughts on “How To Remove Teflon Coating”

Pingback: Why is metal often used for cooking pans? looking for non-toxic cookware?

Thank you a lot for providing individuals with such a marvellous opportunity to read in detail from this web site. Its usually very excellent plus jam-packed with a lot of fun for me and my office friends to search your website more than 3 times in a week to see the newest things you have got. And of course, Im also certainly astounded with the eye-popping strategies you give. Selected 4 ideas on this page are definitely the most suitable weve had.